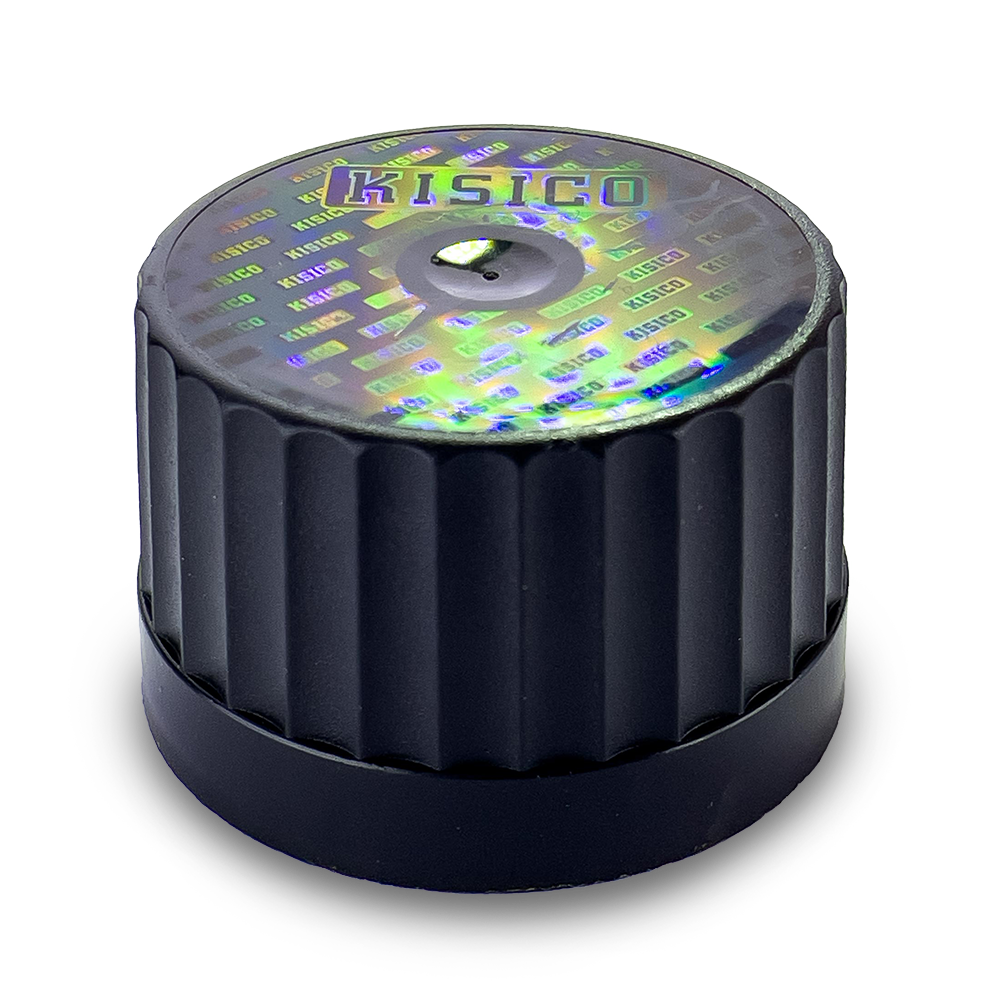

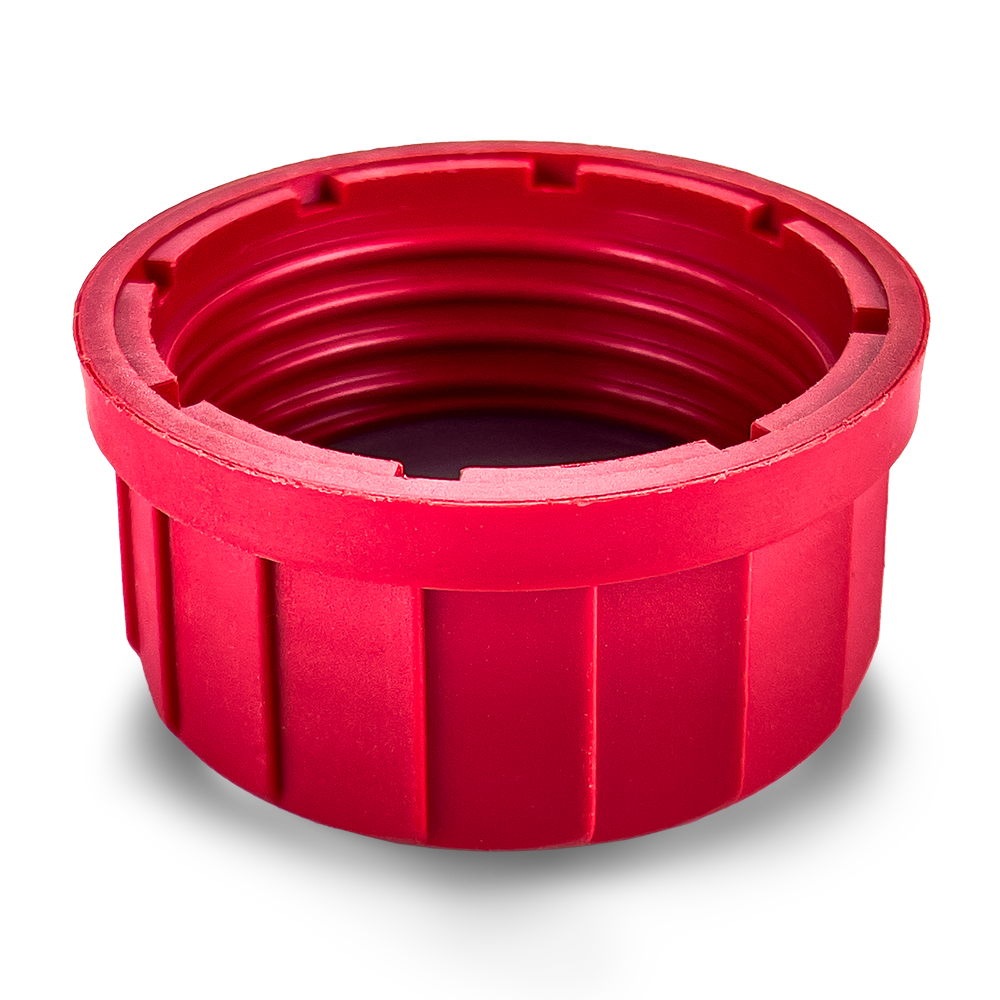

Hochwertige Schraubverschlüsse und Kappen vom Experten

KISICO ist ein renommierter deutscher Hersteller von spritzgegossenen Kappen und Verschlüssen. Mit modernsten Anlagen und umfangreichem Know-How sind wir in der Lage, hochwertige und anspruchsvolle Verpackungskomponenten für die unterschiedlichsten Branchen zu entwickeln und zu produzieren.

Sprechen Sie mit uns über Ihre Anforderungen und wir unterbreiten Ihnen gerne einen Lösungsvorschlag.

Modernste Spritzgussanlagen für eine Produktion auf höchstem Qualitätsniveau.

Produkte und Produktlinien

KISICO führt sehr viele verschiedene Produkte und Produktvariationen die zum Teil miteinander kombinierbar sind. Finden Sie Ihre Wunschprodukte in unserer Übersicht oder erfahren Sie alles über unsere für Sie zusammengestellten Produktlinien.

Lösungen für verschiedene Branchen

Jede Branche hat ihre eigenen Anforderungen. Lernen Sie unsere branchenspezifischen Lösungen kennen. Selbstverständlich können unsere Verschlüsse in zahlreichen weiteren Bereichen eingesetzt werden.

Nehmen Sie Kontakt auf:

Wenn Sie weitere Informationen, Muster, einen Kostenvoranschlag oder eine fachkundige Beratung wünschen, stehen wir Ihnen gerne zur Verfügung.

Sie erreichen uns unter der Telefonnummer:

(06723) 9965 0 oder per Mail unter: info@kisico.de